At Stenzel Sealing Solutions, our reverse engineering capabilities have been honed after 40 plus years of working in the field at the plant level. We understand the critical need to replace obsolete parts with as close to a perfect match as possible. When an OEM asset is no longer available, or no longer affordable, we can reverse engineer a component or the whole assembled asset. Our engineers have the most advanced tools available to get any industrial reverse engineering job done, at the customer’s facility or ours.

What Is Industrial Reverse Engineering?

70% of America’s industrial manufacturing facilities are more than 20 years old. This means asset management and up-time become critical factors in a facility’s success, efficiency, and profitability. In many cases, industrial facilities have assets that are no longer made or supported by the original equipment manufacturer. This results in the situation being even worse on a component level.

Quite often, we find that our customers no longer have records of their oldest equipment. Commonly, they do not have accurate infrastructure documentation from years of maintenance and repair activity. When a facility goes into maintenance turnaround, it’s critical to know assets being repaired, replaced, components that go into them, and components attached to them.

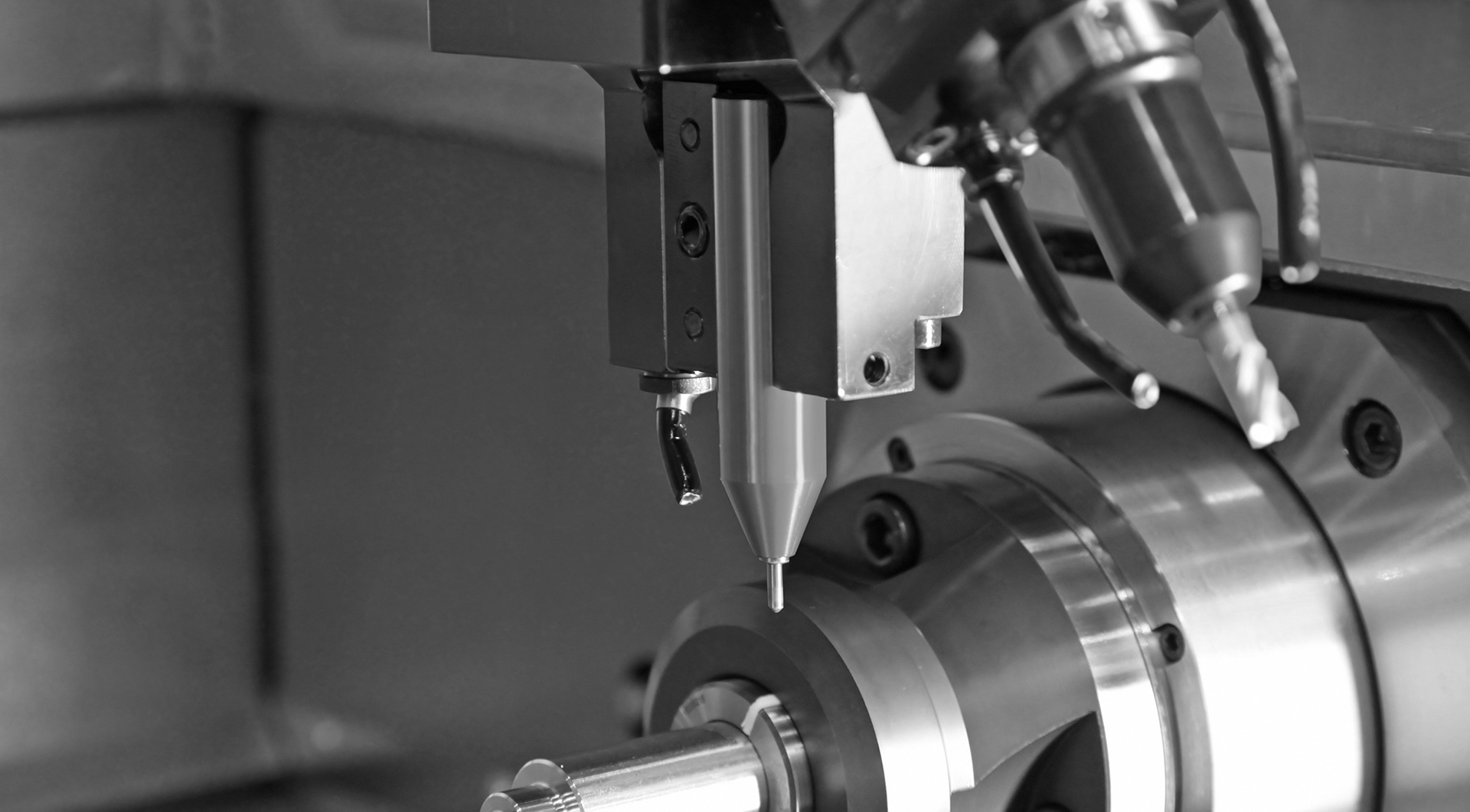

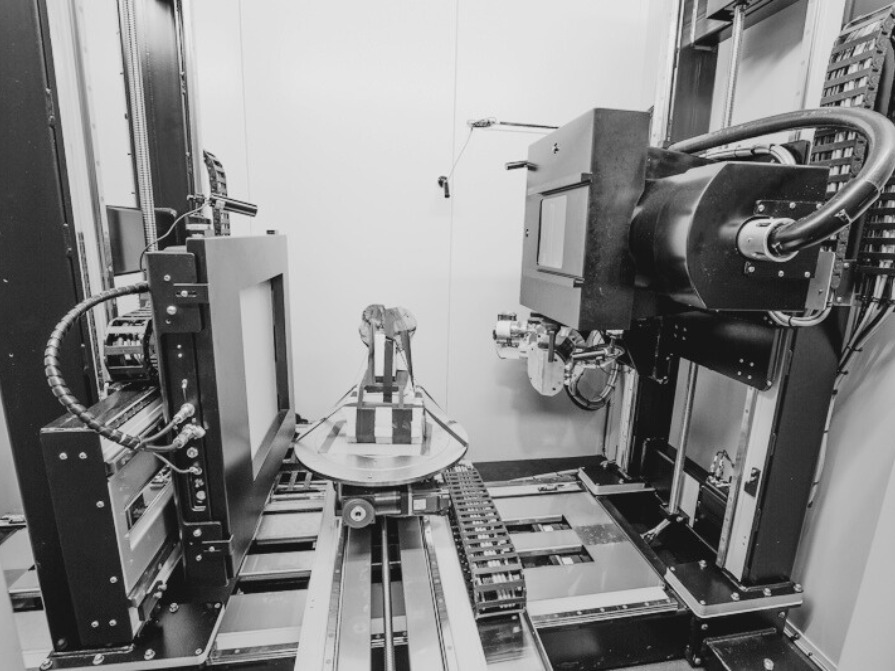

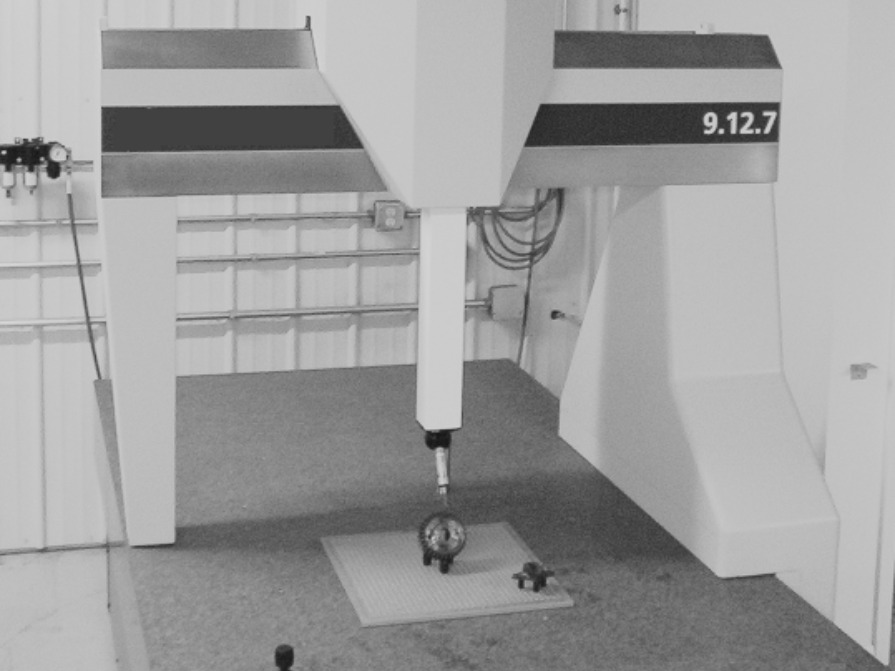

Gone are the days of only relying on charcoal traces on paper, caliper and vernier measurements, and inaccurate measuring tape methodology to reproduce your critical parts and equipment. We can deploy advanced digital 3D scanning tools to achieve accuracy to 0.004” (0.1mm). With fast and accurate post image processing, we can turn plant-level scans into 3D CAD models in several hours, not weeks. When you need a solution, we can provide one, quickly and accurately.

Our technical team has over 100 years of experience with all types of:

We apply our extensive knowledge and manufacturer level training to every situation we encounter to ensure that we capture every necessary detail. Our end result is a replacement item that exactly meets your criteria – a direct replacement or an engineered upgrade. Our industrial reverse engineering services provide:

- Value-added cost savings

- Improved performance

- Shorter lead times (than sourcing the OEM part if it is still available)

Industrial Reverse Engineering Process

To conduct reverse engineering, we will obtain a sample of the product and disassemble it to analyze its internal mechanics. This process allows engineers to reveal details about the initial design and assembly of the product. It is essential to start by analyzing the dimensions and attributes of the product. During this analysis, measurements of the widths, lengths and heights of components in the product are made.

3D scanning technologies are often used to make these sorts of measurements. Common 3D scanning technologies include coordinate measuring machines (CMM), industrial computed tomography (CT) scanners, laser scanners and structured light digitizers.

What is the Purpose of Industrial Reverse Engineering?

GET IN CONTACT WITH US

Submit the form below and we will be in touch with you shortly.