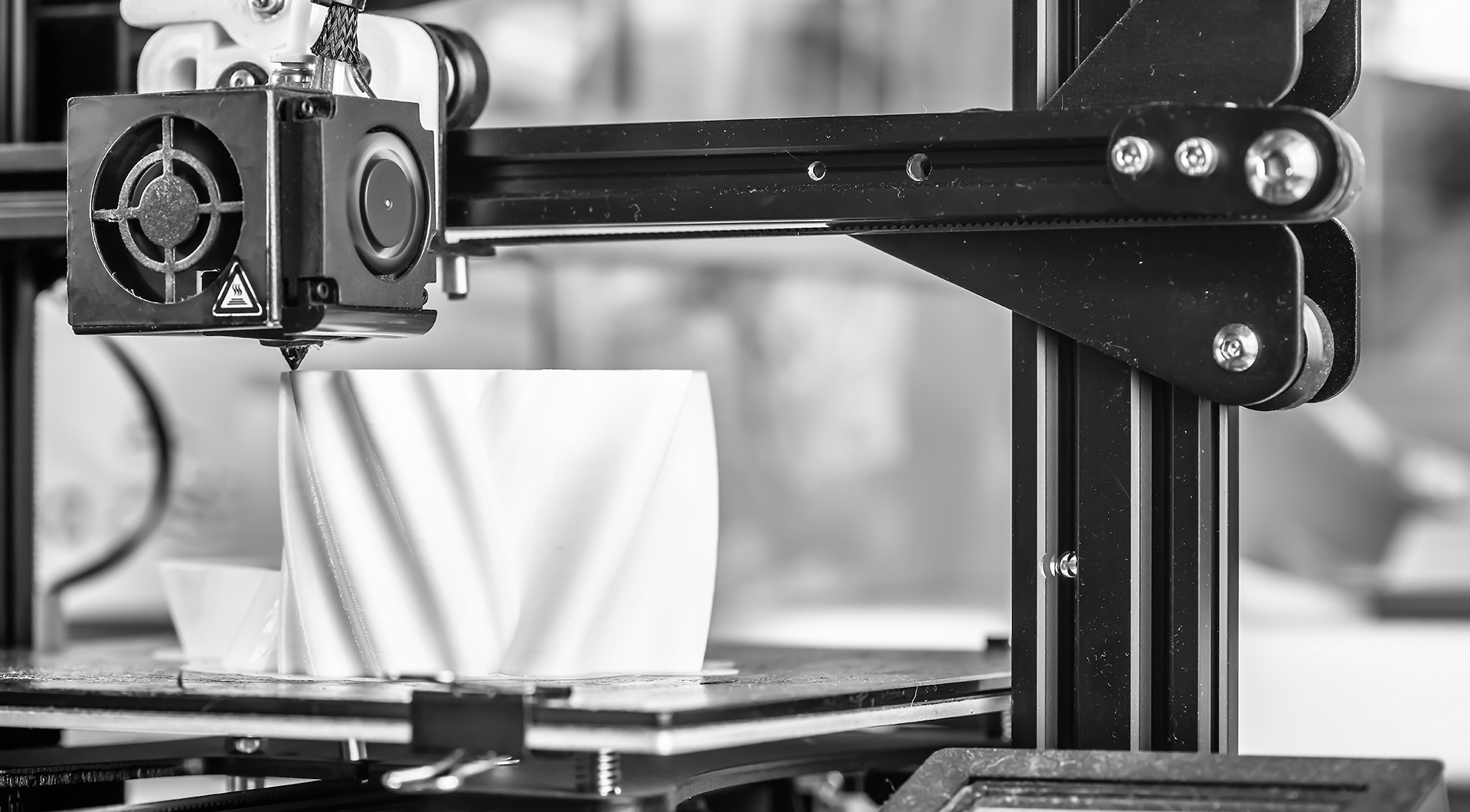

3D Parts Printing

As 3D printers and printing materials continue to advance, Stenzel Sealing Solutions uses our advanced industrial applications knowledge to ensure these latest technologies meet the strict requirements of our customers and application specifications. With many reverse engineered seals projects that we get involved in, prototyping and testing is highly desired before investments in expensive custom tooling assets are made. 3D printing technology allows us to go deep into the reverse engineering process, at a minimal cost, and with quick speeds and agility, to define final parts before going into production mode. Some project specifications allow standard 3D printing materials to be accepted for final use – contact us with your project parameters and we can help determine the best solution for your desired outcome.

Most of what we print are Thermoplastic Elastomers (TPEs) which are polymers that exhibit elasticity similar to that of cross-linked rubber. Elasticity, fatigue resistance, temperature resistance, impact strength, tensile strength, chemical resistance, and dielectric properties are determined by the type of TPE and its chemical structure. TPE technology has not advanced yet to the point of being able to print “pure” NBR, SBR, EPDM, FKM, or Viton elastomers, but there are available materials which can often mimic most of the critical properties of these common sealing elastomers, and we ensure that material selection will meet application requirements.

TPEs can be broken down into 3 categories of printable material: Thermoplastic Polyurethane (TPU); Thermoplastic Co-polyester (TPC); and Thermoplastic Polyamide (TPA).

- TPU is the most common type of TPE used in 3D printing, and exhibits better chemical resistance to oils and greases, high abrasion resistance, and the best rigidity. TPU typically has a Shore hardness range between 60A and 98A. TPC is a co-polyether ester with alternating, random length sequences of either long-chain or short-chain glycols with hard and soft segments.

- TPC is considered to be an engineered-grade material and exhibits good chemical resistance, high strength, good thermal stability, and high temperature resistance. TPC has a hardness range between 85A and 72D.

- TPA is a co-polymer of TPE and exhibits great flexibility, exceptional durability, good heat resistance, and good elasticity. TPA has a hardness range between 63A and 75A.

Obsolete Parts Replacement & Upgrading

With today’s rapid pace of technology advancement and with increasing numbers of mergers and acquisitions between manufacturers, equipment reaches its end-of-life sooner than ever before, bringing with it the challenges of finding parts for this discontinued equipment. The technical team at Stenzel Sealing Solutions has a deep understanding of the applications in the industries we serve, and when parts become obsolete, we have an extensive library of manufacturer’s part numbers, drawings, and specifications to draw from as a baseline to get our customers the replacement parts they need.

At the speed of these equipment advancements also comes changes to the processes and parameters of the systems the equipment was originally installed. Fluid and gas media change just as quickly, sometimes compromising other components and seals. Our technical experts can work with the information in our library and troubleshoot the immediate situation with the site team, and select the best upgraded replacement material or component to ensure effective seal integrity and/or operation for years to come.

Application Analysis & Troubleshooting

The subject matter experts at Stenzel Sealing Solutions have over 100 years of combined time in the field and have seen countless products, applications, and systems. Our vast experience working with on-site maintenance crews, reliability engineers, and design engineers is applied in real time to your specific application, giving you a deep analysis of the root cause issues, and then troubleshooting as safely and expeditiously as possible to get you back up and running.